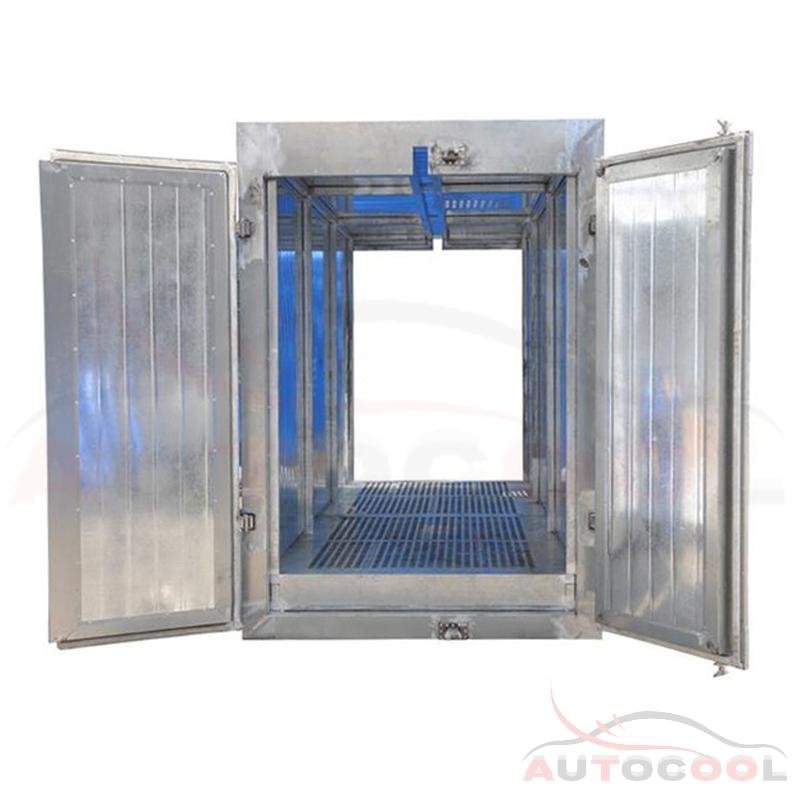

Manual Powder Coating Spray Booth PCBM-1517

PCBM-1517 Powder coating booth provides a bright and clean environment for spraying process. Space-saving manual powder booth features easy and economical for powder application of small and medium-sized workpieces.

An integrated and innovative powder collection module is designed for effectively capturing oversprayed powder. The pneumatic controlled pulse-jetting system regularly cleans filter to prevents powder accumulation and extend filter life.

How does powder coating booth work?

The powder spray booth fan draws air through filters that creates a negative pressure in the chamber, thus oversprayed powders in the air flow will gather in the filters while an automatic pulse-jetting device cleans the filter by interval, through which powders drop into a recovery hopper beneath the booth.

Manual Powder Coating Booth Feature:

1. A high-performance fan efficiently circulate air with low noise and less energy.

2. 0.1 Micron high-precision filters ensures only particle-free air discharged to workshop and increase powder recovery rate.

3. Powder-coated steel constructed booth is corrosion resistant for longer service life.

4. A removable powder hopper at booth bottom simplifies the utilization of recovery powders

6. A user-friendly PLC panel integrates all functions, such turning on / off fans, setting pulse-jetting time and interval, light on/off, emergency stop etc.

Manual Powder Coating Booth Specifications: