MCO-1515 Small Gas Powder Coating Oven

Applying indirect-fired gas heating system, MCO-1515 powder coating oven ensures excellent curing effects and stable quality which is friendly to environment. Comparing with electric soured oven, gas furnace leads to remarkably low running costs, economical for these countries whose electricity is expensive.

Application: for batch production of wheels, bike & motorcycle accessories, heat sinks, or other small metal parts.

Gas/LPG/DIESEL Fired Powder Coating Oven Details

PLC Control Panel

The multi-purpose PLC control panel is easy to operate. Allows users digitally setting temperature & time while values displayed on LCD screen. This control system provides a precise heating process.

Other functions such as: Power switch, emergency stop, fan start.

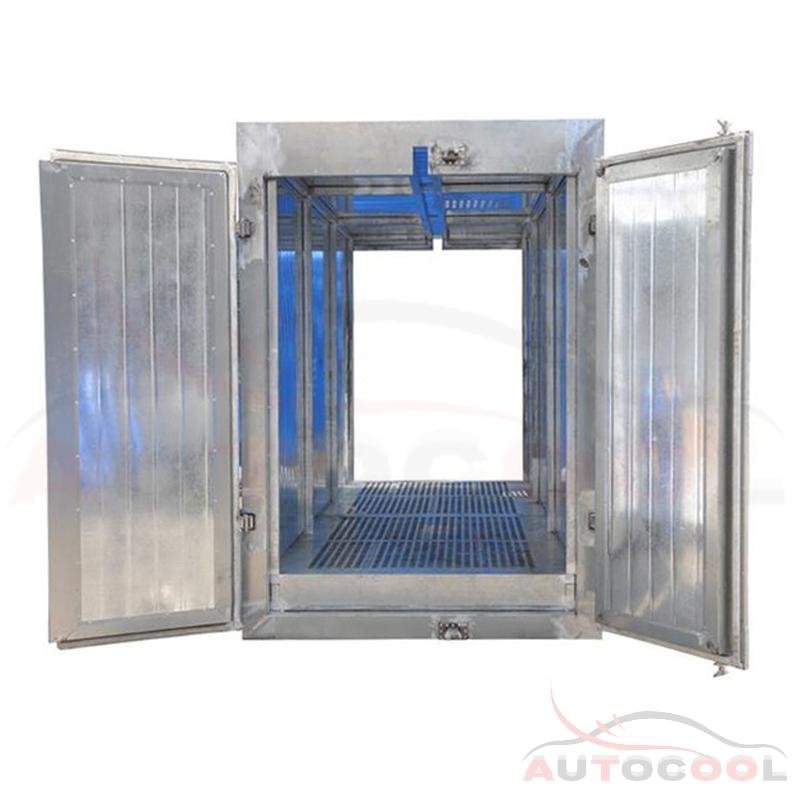

Powder Coating Oven Material

Insulation material is100mm thick rockwool board, density 120kgs/cbm, always keeping a warm chamber with least temperature dropping. Innerwall is heat-resistant galvanized steel, outer wall is anti-rust color steel, durable with a long service life.

RIELLO Gas Burner

An imported Riello burner takes full utilization of fuels, saving energy at the same time giving much quicker raise to a required temperature. The combustion process is clean and pollution-free.

Heating Exchanger

Heating exchanger inside the combustor that transfer clean hot air to oven chamber, It combines seamless steel tube 8×8 array, made of 310S stainless steel with 3-4mm thickness.

Circulation Fan

Powerful fan speeds up the flow of hot air ensures uniform heat distribution with temperature stability less than 3 degree, leading to quality cured finishes and optimum cure cycles.

Transporting System

It is an inexpensive manual transport solution that allows loading of heavy elements using a small amount of force. Standardly equipped with two trolleys, inner trolley moves across the hall that does not contaminate the inside of the oven, ensures high purity painted elements. Custom design is available to get a optimal use of the entire space of oven.

MCO-1515 Electric Powder Coating Oven Specifications

| Working dimensions | Width1500 x Height1500 x Depth1500 mm |

| Overall dimensions | Width1900 x Height2200 x Depth1700 mm |

| Power supply | Gas / Diesel / LPG |

| Voltage | 380V/220V (Custom Voltage Available) |

| Frequency | 50-60hz |

| Warm-up time | 15-30 min. (180° C) |

| Temperature stability | < ± 3-5°C |

| Temperature max | 250° C |

| Ventilation performance | 805-1677m3/h |

| Motor power | 0.75kw |

| Circulation/ Air flowVertical | Variable through holes on the walls |

| Transportation | Trolley |

| Burner | Italy RIELLO. 50.000CAL |