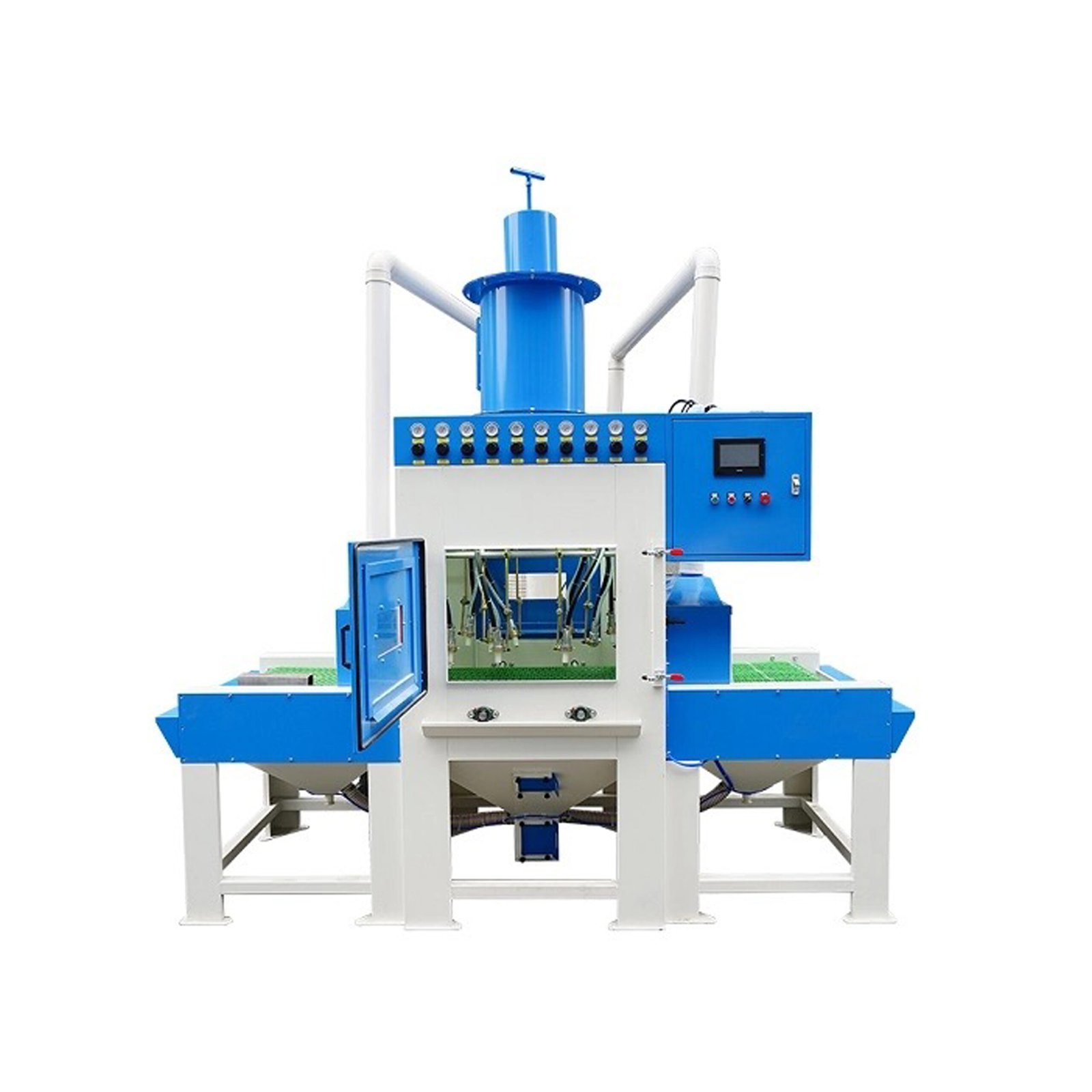

Double Station Pressure Sand Blast Cabinet

The pressure blast cabinet is specially designed with 2 working stations, which is required to operate larger workparts. Unlike normal blaster sucking medias, this machine works by compressed air directly pushing and accelarating the medias to blast gun nozzle, then blasting them out onto the target surface.

As the medias are delivered at a much higher velocity that causing powerful cutting force, pressure blast cabinet is ideal for tough cleaning jobs, such as removing heavy burrs, thick oxide layers and old coats, or treating hard materials, work can be done 3-5 times faster than a suction blast cabinet.

Pressure Blast Cabinet Features

1, Enclosed cabin design without dust leakage during blasting, cause no pollution to environment and is safe to operators.

2, Built with filter cartridge collector to capture even ultrafine dust, filter is automatically cleaned by pulse valve. It ensures vented air is clean.

3, Used abrasives are collected in the funnel that can be recycled for many times, reducing consumption and save cost.

4, Newly-developed pressure abrasive valve improves processing quality, reduces compressed air consumption.

5, Pressure type blast gun with boron carbide nozzle are extremely durable that guarantees long service life.

Double Station Pressure Blast Cabinet Specifications