Product Description

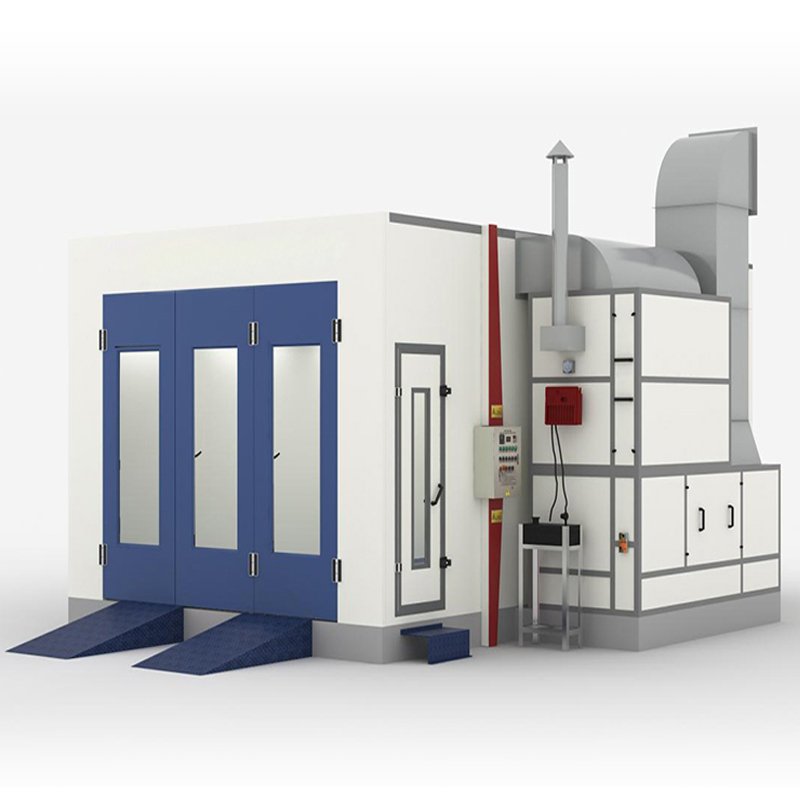

CAR PAINT SPRAY BOOTH PAINT CHAMBER CE CERTIFICATED

Specification:

Outer Size: | 7000 x 5350 x 3500mm | Inside Size | 6900 x 3900 x 2650 mm (L x W x H) |

Foundation and Floor | Foundation | Full metal foundation, two rows flat steel grids and three rows metal non-slip diamond plates. (Entire floor with grilles optional) | |

Metal basement | 280mm height. (Without basement inner floor same level with ground optional) | ||

Drive-in Ramps | 3Units, each size: 2000X970mm, diamond plate construction | ||

Wall and door | Wallboard and Roof Panel | High quality double construction fireproof insulation EPS panel, thickness: 75mm (PU / Rock wool wall panel optional) | |

3-Folded Entrance Door With Safety Glass Window | 1 set, Entrance door made from SUS304 stainless steel, 3000×2600 mm(W x H) three folds, Luxury windows.Stronger and More durable than other normal aluminum alloy edge doors easy to be out of shape. (luxurious glass window door optional) | ||

-Operator’s Door With Safety Glass Window | Big opening:700x2000mm (W x H),hand-made, tempering glass observation window | ||

Light System | Ceiling Lighting | 8Units, each 4×16W, Total 512W , adopt LED Lamp | |

Side Lighting | 8Units, each 4×16W, Total 512W , adopt LED Lamp | ||

Brightness | ≥1000 LUX | ||

Filtration System | Primary filters | Filtration Class G3 & Flame Resistance F-1 plate type prolonged and hardened fiber | |

Ceiling Filters | Flame Resistance F-1 & EU5 grade high efficient filter | ||

Bottom filter & exhaust filter | Flame Resistance F-1 &Grade G2 Fibreglass paint-stop filter, add M-type carbon filter. | ||

Ventilation System | Inlet fan and Outlet fan | Two sets air fans 7.5 kw centrifugal; one sets for air-intake, one for air-outlet, One cabinet for fans + three Air ducts + one electric air damper. | |

Painting and baking exchange system | Solenoid valve+ pressure adjustment control cylinder driven damper exchange | ||

Total fan Capacity and Air flow speed | 40,000m³/h, 0. 4m/s in empty booth , 0.45m/s in loaded booth | ||

Water based paint drying system | Four corner with drying boxes, motor capacity 350w *4units, nuzzles 40pcs in total. | ||

Heating Ex-changer | Adopt high efficient heat-resistant stainless steel as cycling heat ex-changer | ||

Heating System | Heating Exchange Capacity | 215KW(200,000Kcal/H) | |

Burner Model | Adopt Italy RIELLO diesel burner G20(200,000kcal/h), Fuel consumption 7.5~14.5kg/h (Gas burner FS20 optional) | ||

Heating time | 5-7minutes (from20 to 60º under baking status, max baking temperature is 80° | ||

Control system | Standard control system | ||

Control Board | Function | Painting, warm painting, baking, lighting, emergency stop switch, failure indication, over-temperature alarm indication | |

Total power | 16.5 KW | ||

Voltage | 380V/ 3PH/ 50HZ | ||

Note: Due to product improvements design, specifications are subject to change without notice.