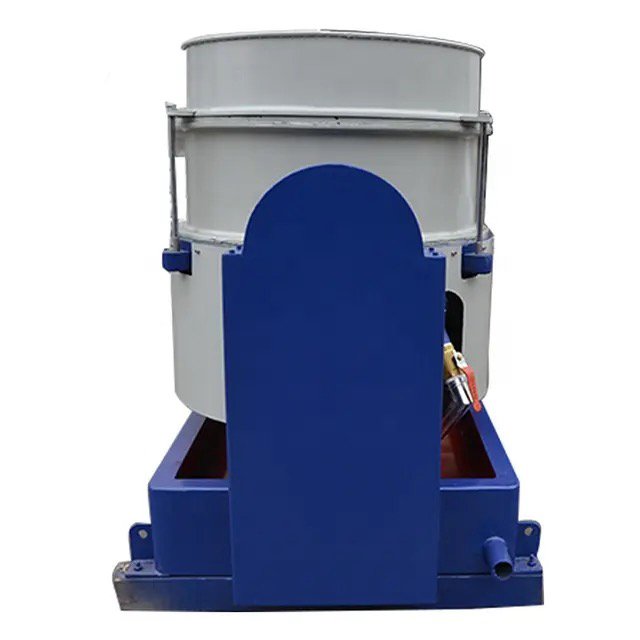

Centrifugal Disc Polishing Machine Feature

1. Belt drive or motor direct drive.

2. Manual or automatic unloading.

3. Speed regulating motor or variable frequency speed regulating motor.

4. Optional stainless steel gasket to reduce gaps, prevent product jams and extend machine life.

5. Optional separate function to separate products, polishing media and polluted water at same time which can greatly improve production efficiency.

Product Paramenters:

Model | Capacity (L) | Size L*W*H(mm) | Drum Speed (rpm) | Power (kw) | Barrel Diameter (mm) | PU Thickness (mm) | Weight (Kg) |

CDF-50 | 50 | 1400*850*1200 | 0-220 | 1.5 | 480 | 20 | 400 |

CDF-120 | 120 | 1700*950*1400 | 0-220 | 4 | 690 | 25 | 600 |

CDF-50B | 50 | 1100*750*1200 | 0-220 | 1.5 | 480 | 20 | 300 |

CDF120B | 120 | 1290*1000*1570 | 0-220 | 4 | 690 | 25 | 500 |

CDF-120A | 120 | 2050*1100*1570 | 0-220 | 4+1.1+0.18 | 690 | 25 | 1000 |

CDF-120C | 120 | 1200*1950*1200 | 0-220 | 4+1.1+0.18 | 690 | 25 | 900 |

CDF230C | 230 | 2000*1900*2060 | 0-160 | 7.5*2.2+0.36 | 1000 | 25 | 1500 |

Application

Rubber products, O-rings, seals, jewelry, precision parts, etc.