Product Description

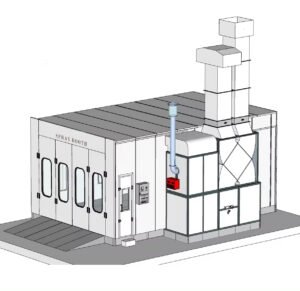

CAR PAINT SPRAY BOOTH WITH HEATING RECYCLE SYSTEM CE CERTIFICATED

Specification:

Outer Size: | 7000 x 5350 x 3500mm | Inside Size | 6900 x 3900 x 2650 mm (L x W x H) |

Foundation and Floor | Foundation | Full metal foundation, two rows flat steel grids and three rows metal non-slip diamond plates. (Entire floor with grilles optional) | |

Metal basement | 280mm height. (Without basement inner floor same level with ground optional) | ||

Drive-in Ramps | 3Units, each size: 2000X970mm, diamond plate construction | ||

Wall and door | Wallboard and Roof Panel | High quality double construction fireproof insulation EPS panel, thickness: 75mm (PU / Rock wool wall panel optional) | |

3-Folded Entrance Door With Safety Glass Window | 1 set, Entrance door made from SUS304 stainless steel, 3000×2600 mm(W x H)three folds, Luxury windows.Stronger and More durable than other normal aluminum alloy edge doors easy to be out of shape. (luxurious glass window door optional) | ||

-Operator’s Door With Safety Glass Window | Big opening:700x2000mm (W x H),hand-made, tempering glass observation window | ||

Light System | Ceiling Lighting | 8Units, each 4×16W, Total 512W , adopt LED Lamp | |

Side Lighting | 8Units, each 4×16W, Total 512W , adopt LED Lamp | ||

Brightness | ≥1000 LUX | ||

Filtration System | Primary filters | Filtration Class G3 & Flame Resistance F-1 plate type prolonged and hardened fiber | |

Ceiling Filters | Flame Resistance F-1 & EU5 grade high efficient filter | ||

Bottom filter & exhaust filter | Flame Resistance F-1 &Grade G2 Fibreglass paint-stop filter, add M-type carbon filter. | ||

Ventilation System | Inlet fan and Outlet fan | Two sets air fans 7.5 kw Turbine; one sets for air-intake, one for air-outlet, One cabinet for fans + three Air ducts + one electric air damper. | |

Painting and baking exchange system | Solenoid valve+ pressure adjustment control cylinder driven damper exchange | ||

Total fan Capacity | 50,000m³/h | ||

Air Flow Speed in cabin | 0. 4m/s in empty booth , 0.45m/s in loaded booth | ||

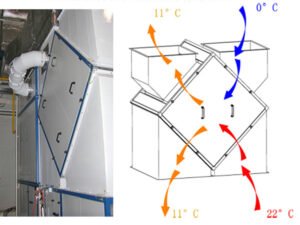

Heating Ex-changer | Adopt high efficient heat-resistant stainless steel as cycling heat ex-changer | ||

Heating System | Heating Exchange Capacity | 215KW(200,000Kcal/H) | |

Burner Model | Adopt Italy RIELLO diesel burner G20(200,000kcal/h), Fuel consumption 7.5~14.5kg/h (Gas burner FS20 optional) | ||

Heating time | 5-7minutes (from20 to 60º under baking status, max baking temperature is 80° | ||

Heating recycle system | Heat regenerator, When warm painting, the energy-saving system can collect exhaust air’s energy to heat the cold fresh air, then through second heating by furnace, the temperature of air in cabin will be increased quicker, more energy-saving, more environmental. | ||

Control Board | Function | Painting, warm painting, baking, lighting, emergency stop switch, failure indication, over-temperature alarm indication | |

Total power | 16.5 KW | ||

Voltage | 380V/ 3PH/ 50HZ | ||