Preparation Bay Station:

1. External dimensions of the single-station room: length 7000*width 3550*height 3400mm, (excluding the size of the overhead fan)

2. Internal dimensions of the single-station room: length 6900*width 3450*height 2645mm,

3. The left transparent observation tempered glass wall, the back wall uses 50mm hand-purified rock wool board, double-sided color steel plate 0.5mm, rock wool density 100kg. The right side wall uses PVC electric

roller shutter, gray. The column is made of 50*100mm square tube.

4. The front door uses PVC electric roller shutter, gray on the top, transparent in the middle, and gray on the bottom.

5. The base system is composed of 30*5mm galvanized steel grille and 40*80 square tube beam, 5 ground grilles; the platform enclosure is made of 0.8mm galvanized sheet, with a total height of 280mm;

6. The air supply system is composed of 1 1.5KW energy-saving fan, and the exhaust system is equipped with a combined tool cabinet, power socket, and quick interface (size length 3450* width 1200* height 1570mm), equipped with 1 5.5KW centrifugal fan, with a total air volume of 15000m3/h;

7. The exhaust duct is composed of high-quality galvanized steel plate and flanges made of professional equipment; equipped with φ 600 round wind tube 2 meters, with 1 elbow and 1 bend;

8. Filtration system: primary filtration at the air inlet, produced with Italian technology, effectively captures more than 10um dust particles; high-efficiency filtration on the top, produced with Dutch technology, can efficiently capture dust particles larger than 4um, with a capture rate of ≥98%, built-in filter cotton bracket, convenient replacement of filter cotton, glass fiber cotton at the bottom.

9. 8 sets of ceiling lights × 4 pieces = 32 pieces × 16W, LED lamp tubes, light box flat installation, illumination: ≥800LUX;

10. No heating;

11. The electric control box is equipped with: leakage protection, painting, lighting, power supply, emergency stop switch, etc., and the main electrical appliances are Delixi electrical appliances.

12. Equipped with 5 tracks and 4 side-shift rail cars.

Car Paint Spraying Station

1. External dimensions of the room: length 7000*width 4000*height 3400mm, (external height does not include the size of the top water-soluble fan)

2. Internal dimensions of the room: length 6900*width 3900*height 2645mm

3. The wall is made of 50mm hand-purified rock wool board, double-sided color steel plate 0.5mm, rock wool density 100kg. The left side wall uses PVC flame-retardant cloth electric rolling shutter door, built-in tubular 220V

motor, with wireless remote control. The size is 6000*2200mm, and the rolling shutter door frame is made of 50*100mm square tube spray.

4. The front door is a large aluminum alloy glass door, 4 doors, with a size of 3000mm wide and 2600mm high.

5. A set of large aluminum alloy glass safety doors on the side, with a size of 650*2000mm.

6. The base system is composed of 30*5mm galvanized steel grilles and 40*80 square tube beams (2 steel grilles and 3 patterned plates); the platform enclosure is made of 0.8mm galvanized plate, with a total height of 280mm;

7. The air supply system is composed of a 7.5KW European turbine fan, and the exhaust system is composed of an activated carbon integrated machine (1 layer of activated carbon, about 200 pieces, size 4000*1200), equipped with a 7.5KW European turbine fan, air volume 25000-30000m3/h;

8. The exhaust duct is composed of high-quality galvanized steel plates and flanges made of professional equipment; equipped with a φ 700 round wind tube 2 meters, with 1 elbow and 1 bend;

9. Filtration system: primary filtration at the air inlet, produced with Italian technology, effectively captures more than 10um dust particles; high-efficiency filtration on the top, produced with Dutch technology, can efficiently capture dust particles larger than 4um, with a capture rate of ≥98%, built-in filter cotton bracket, convenient replacement of filter cotton, bottom glass fiber cotton, exhaust cabinet photocatalytic activated carbon filtration.

10. 8 sets of ceiling lights × 4 = 32 × 16W, LED lamp tube, external light box, illumination: ≥800LUX;

11. Heating system: Riello FS20 natural gas burner, stainless steel heat exchanger, maximum drying temperature 60 degrees Celsius;

12. The electric control box is equipped with: leakage protection, time setting, painting, lighting, emergency stop switch, etc., and the main electrical appliances are Delixi electrical appliances.

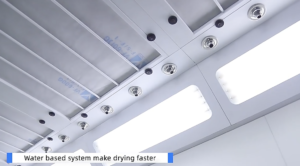

13. A water-soluble paint flash drying device is installed on the top, equipped with 40 sets of stainless steel nozzles and 2 0.55kw air compressors.

14. Equipped with 5 tracks and 4 side-shift rail cars.

*****Note: The above configuration is a 2-station spray line, which can be designed according to customer needs.